A guide to temperature sensor design

Temperature is the most frequently measured parameter in the world, yet it is difficult to measure accurately. The most commonly-used devices for electrically measuring temperature are thermocouples, temperature-dependent resistance elements – RTDs and thermistors – and semiconductor diode elements. While methods for using these are well-known, the challenge comes when attempting to measure with an accuracy of better than 0.5°C or 0.1°C. Overcoming these challenges and integrating the sensors into CPU-based control or monitoring systems requires expertise in analogue and digital circuit design, and firmware development.

This article is intended to help engineers tasked with designing temperature sensors into their systems, whether for direct monitoring or control, protection against overheating, or calibration of other temperature sensitive sensors or system components such as gas and flow meters. When initially considering temperature sensor types for integration into a new application, the first questions relate not so much to how ‘good’ a sensor may be – that will come later – but rather to how well matched to the application it is.

Accordingly, we start by looking at the factors that dictate which sensor type is best for any given application. We then review the different sensor types available, so that their comparative benefits and drawbacks become apparent. Armed with these comparative profiles, we proceed to look at some more in-depth practical considerations; approaches to take and points to consider when designing these sensors into real applications. We finish by highlighting some currently available kits and hardware that you can use to get started with your sensor system design.

Consider your application, and match your sensor to it

Sensors are characterised by many parameters, which can be broadly classified into electrical, physical and environmental types. Sensors’ profiles in terms of these parameters can be compared with an application’s requirement specifications to identify the best fit. For example, a home thermostat does not need very high accuracy, but it should be low-cost for high volume production. By contrast, price is probably less critical for a medical instrument sensor, but high accuracy, resolution and noise immunity is usually essential.

Different applications will make varying demands on a sensor’s accuracy. Any consideration of ‘accuracy’ should also extend to the related characteristics of discrimination and precision . Accuracy is the capacity of a sensor to give results close to the true value of a measured temperature, while discrimination is the minimal change of input required to produce a detectable change in output. Precision defines the sensor’s ability to give the same reading when repetitively measuring the same variable under the same prescribed conditions.

A temperature probe will also be prone to errors, which can be either systematic or random. Systematic errors can arise from drift, or where the measurement process changes the measurand (loading error). Extracting the signal from the sensor for transmission can also change or attenuate it. Random errors can be caused by noise, which can be created by EMI, thermocouple effects, thermal gradients between the sensor and material being measured, tolerances, trace resistance and leakage current.

The sensor’s input range span in terms of maximum and minimum temperature is clearly critical, but related parameters also apply. Sensitivity, for example, is important when integrating sensors to their associated measuring circuits; it is defined as the slope of the calibration curve y = f(x). A sensor can also exhibit sensitivity-related errors, such as saturation and ‘dead-bands’. Linearity, or the closeness of a calibration curve to a specified straight line, is a major issue for most sensors, and will be discussed more later.

In some instances, the sensor’s dynamic characteristics are also important. How do physical masses, inductances or electrical or thermal capacitances affect the sensor’s dynamic response to an impulse, step or other input change?

In many applications, a temperature sensor’s resilience to its target environment can be as important as its technical characteristics. If corrosion occurs, for example, the sensor conductor’s cross-sectional area will be reduced, increasing its resistance and affecting its accuracy. For RTD-type sensors, this makes the choice of a noble metal like platinum attractive, as it prevents this problem. Contamination, by contrast, can reduce resistance by establishing an alternative or shunt path along the outside of the element. Both contamination and corrosion can contribute to drift and reduced stability in the sensor output.

Prolonged mechanical shock and vibration can alter sensor readings, or possibly result in intermittent or complete failure. Sensor drift and reduced stability can also result. RTD probes, for example, can be vulnerable at the connection between the element and sensor lead wires. A typical RTD will specify shock resistance to 100G of 8ms duration, and vibration immunity to 20G from 10Hz to 2KHz.

Extreme temperatures, wet locations or reactive materials can reduce insulation resistance, setting up a shunt path between the element and case which will lower apparent readings. Accordingly, sensors can be specified as chemically resistant, IP rated, ATEX approved, or specified for high vibration environments. Conversely, its effect on the environment that it is intended for may need consideration; it may need rating for food use, for example.

The way in which the probe interacts with its environment physically also requires critical consideration. What are the dimensions of its target mounting space? What arrangements need to be made for mounting it? How will it be connected into its associated electronic circuit?

There are other factors affecting sensor choice, including ease of setup and use, calibration, and whether the sensor needs an excitation current to operate. Last but certainly not least there are also the cost considerations associated with sensor choice. However, these factors will be discussed in the comparison of sensor types given below.

Different temperature sensor types available

The four contact temperature sensor types currently in popular use include thermocouples, Resistance Temperature Devices (RTDS), thermistors and silicon IC types.

Thermocouples

Thermocouples are popular because of their attractive pricing, simplicity, fast thermal response, wide temperature range and ruggedness. Their use is simplified in that they do not require an excitation supply. However, they are of limited accuracy, highly non-linear and require significant linearization algorithms. Additionally, their voltage output is relatively low when compared to devices that can convert voltage signals to a digital representation. Consequently, analogue gain stages are required in their control circuit.

A thermocouple comprises two thermoelements (wires) of different materials joined at one end, called the junction or measuring end. The other end of the thermocouple is called the tail end or reference end. The junction end is in contact with or immersed in the environment whose temperature T2 has to be measured, while the tail end is held at a reference temperature – ambient, for example.

Because of the temperature difference between junction end and tail end, a voltage difference can be measured between the two thermoelements at the tail end, so the thermocouple is a temperature-voltage transducer.

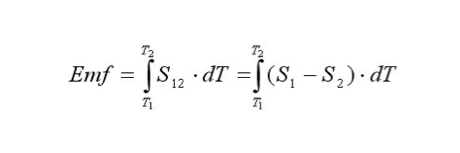

The temperature vs voltage relationship is given by Equation 1:

Equation 1: Thermocouple temperature-voltage relationship

Where EMF is the Electro-Motive Force or voltage produced by the thermocouple at the tail end, T1 and T2 are the temperatures of reference and measuring end respectively, S12 is called the Seebeck coefficient of the thermocouple, and S1 and S2 are the Seebeck coefficients of the two thermoelements; the Seebeck coefficient depends on the thermoelement material. The Seebeck coefficients are temperature dependent.

Equation 1 also shows that the thermocouple EMF depends on both T1 and T2. Accordingly, the tail end should ideally be maintained in an ice bath to provide a reference temperature of 0°C. However, in real industrial applications, the ice bath is usually replaced by a cold junction compensation IC.

Thermocouples are designated by letter types B, R, S, K, N, E and J, according to their voltage-temperature relationship as shown in Fig. 2. More detailed information on the voltage-temperature relationship for letter-designated thermocouples can be found on the US National Institute of Standards and Technology (NIST) website.

Fig.1 Voltage – temperature relationships for letter-designated thermocouples - Image: ©Premier Farnell Ltd

Applications include high temperature furnaces, ovens and kilns, rocket engines, gas appliance safety monitoring, chemical production and petroleum refineries, food processing and production, and iron, steel and aluminium production and smelting.

Thermistors

Thermistors are usually metal-oxide ceramic semiconductor sensing elements. They can have either a positive (PTC) or a negative (NTC) temperature coefficient, but NTC types are typically used for temperature sensing and compensation. They are low cost and available in small form factors with a wide range of packages. They offer high accuracy (usually to within +/- .05% to +/- .02%) and sensitivity over a narrow temperature range, and work with a small excitation current, which reduces loss in wires. They have good electrical noise immunity, and are easy to interface to electronic instrumentation.

Their main disadvantage is that their resistance-temperature characteristic is very nonlinear at temperatures below 0°C or above 70°C. Their small mass can make them susceptible to self-heating errors, and they can be prone to permanent de-calibration (drifting beyond specified tolerances).

Linearization can be performed in software, using lookup tables. However, circuits for linearizing thermistor outputs can comprise series, parallel and series-parallel combinations of fixed resistors and additional thermistors. The simplest circuit is a parallel resistor whose value can be calculated from Equation 2 below :

Equation 2: Linearizing resistor calculation

Applications include medical devices, home thermostats, temperature monitoring in power supplies, battery chargers, cold junction compensation and overtemperature shutdown.

Resistive Temperature Detectors (RTDs)

Most RTDs use platinum in wire or film form, while some are made from nickel, nickel/iron alloy, or copper. Advantages include high accuracy, repeatability and stability, with low drift error over the range -200°C to +850°C. RTDs provide fairly linear outputs.

RTDs exhibit some nonlinearity, which must be corrected using a lookup table in a microcontroller. They are more expensive than thermocouples and thermistors. They require a current source to operate, and are self-heating; they must balance between excessive bias current leading to inaccuracies, or insufficient current that reduces RTD noise immunity.

A current source of 1 mA or less is usually adequate. Under this circumstance, the accuracy of an RTD can be ±4.3°C over its temperature range. If higher accuracy is required, the Callendar-Van Dusen equation as shown in Equation 3 can be used to generate a look-up table :

Equation 3: Callendar-Van Dusen equation for high-accuracy RTDs

RTD applications include industrial instrumentation, hot wire anemometers and laboratory-quality measurements.

Semiconductor IC sensors

Semiconductor IC sensor development has been driven by automotive, consumer, medical, computer and other applications. They are found embedded in most PCBs and chips.

They offer the best linearity in output and do not require linearization or cold junction compensation. They can be made on the same chip and process as any other electronic chip function, so are easily amenable to high levels of integration. Their high output levels yield good noise immunity, and they are readily interfaced to any other analogue or digital circuit. With a wide operating temperature range, they are qualified for numerous types of electronic circuit – especially as they provide many useful output levels in logic, pulse, digital or analogue form.

Semiconductor IC sensors are found in many automotive applications, including hybrid, electrical and power train systems, and motors. Other applications include enterprise servers, industrial control, building automation, grid automation, medical, healthcare and fitness, test and measurement, remote sensing, display, and personal electronics.

Summary

Fig.2 below summarises the key characteristics of the different temperature sensor types.

Fig.2: Comparison of temperature sensor characteristics - Image: ©Premier Farnell Ltd

Availability of different sensor output signal types

A key advantage of semiconductor or digital sensors is their ability to provide outputs in a useful choice of forms. Microchip’s sensor family includes logic, voltage and bus-compatible serial output types.

Logic output temperature sensor families offer excellent temperature accuracy (±1°C, typical), with a very low operating current of less than 600 µA. These devices can replace mechanical switches in a variety of sensing and control applications.

Voltage output sensors develop an output voltage proportional to temperature, with a nominal temperature coefficient of 6.25 mV/°C and 10 mV/°C, respectively. These temperature-to-voltage converters can sense a –40°C to +125°C temperature range and feature an offset voltage that allows reading negative temperatures without requiring a negative supply voltage. The extremely low operating current minimizes self-heating and maximizes battery life.

Serial output sensors offer excellent temperature accuracy (±0.5°C typical) with a very low operating current of less than 250 µA. Communication with these devices is accomplished via an industry standard SMBus, I2C™ or SPI™ compatible interface protocol. These devices feature very fast temperature conversion times, with temperature resolution for the entire family ranging from 0.0625°C to 1°C.

Practical considerations for temperature sensor integration

Practical factors driving thermocouple choice

Peak Sensors has published a Thermocouple Design Guide, which includes information on how to select the right thermocouple for an application, as shown below. Their selection distribution is represented in Fig. 3, which matches senor types to applications.

Fig.3: Matching thermocouples to applications - Image: ©Premier Farnell Ltd

Moderate and light thermocouples, as suggested in Figure 3, are mainly used within equipment, not driven to their limits, usually used for lower temperatures, and often included within customers’ products. They tend to be high-volume, inexpensive, easy-to-use types, with significant design effort expended in reducing per-unit cost. They are available in three basic design forms:

- Flexible Cable Temperature Sensors

- Rigid Metal Tube Temperature Sensors

- Mineral Insulated Temperature Sensors

Harsh use thermocouples are mainly found in industrial plants, process control and factories. They are manufactured in smaller volumes for higher temperatures and may be resistant to chemical attack, abrasion, pressure and carburisation. They are often driven close to their physical limits and have a higher unit cost, but can be dismantled for repair or precious metal recycling. Their applications typically call for selection of a sheath capable of protecting them from their target environment. These sensors have three basic design forms:

- Ceramic sheaths

- Tough metal sheaths for high temperatures

- Tough metal sheaths for chemical environments

Thermistor operating condition considerations

NTC thermistors – which are used primarily for temperature measurement and compensation - are a sintered mixture of metallic oxides, which include nickel, cobalt, manganese, and sometimes other oxides. The elements are formed as beads, chips, discs, rods, or thin-films. Bead thermistors are drops of semiconductor paste deposited on two platinum alloy wires, sintered at a high temperature. The wires are then cut to make individual thermistors. Chip and disc thermistors are fabricated as a thin sheet of material (wafer), and sintered at high temperature. The sides are silvered for attaching leads, and the wafers are cut into discs or chips. Rod thermistors are simply extruded.

Certain operating conditions can significantly lower measurement accuracy or reliability, and should be avoided. For instance, self-heating might become a hidden accuracy error, as thermistors generate their own heat when their excitation current is too high. Parts with a large dissipation constant, a low thermal resistance mounting, and other means of superior heat dissipation will have a lower temperature rise. But the primary way to avoid excessive self-heating is to keep the excitation current as low as possible.

Most measurement errors and premature failures often come from careless installation and operation. For example, although thermistors are considered to be rugged devices, take care not to crack a case, separate a bond, or exceed the upper temperature limit.

Lastly, aging is a phenomenon that is often overlooked and if not considered in the maintenance schedule, can lead to loss of calibration accuracy after extended periods of use. It manifests as an effective thermistor terminal resistance drift over time due to slowly changing resistances in the bulk material and in the contact areas between the leads and the thermistor material.

Fig.4: Thermistor internal components – Image via Imgur

Common causes of error in RTDs

Self-heating is the single largest problem source when using RTDs. Readings can be impacted particularly when measuring temperatures below 0°C, so it is important to minimise excitation current as far as possible. Errors can also be introduced to measurements through the connection leads; however, these can be reduced using a three-wire connection; even better, a four-wire connection can be used to remove the test lead resistance from the voltage measurement.

Another common mistake is to not select the correct RTD temperature range. Trying to measure outside of the RTD’s specified temperature range can result in greater errors or even sensor damage. Designing in semiconductor temperature sensors – practical considerations

An article published in Sensors Online, Jan 1, 2008 by Emmy Denton contains plenty of useful information on the practical aspects of positioning temperature sensor ICs on a PCB. Much of this is shown below.

IC temperature sensors, in the form of remote diode temperature sensors (RDTSs), are used to monitor diode junctions in highly-integrated power-hungry devices such as CPU ICs, or bipolar transistors. An RDTS with a multiplexer front end can be a cost-effective way to enable several temperature sensing nodes for a system; the implementation techniques discussed may also be applied to other analogue or digital IC temperature sensors.

The standard equation for the base emitter voltage drop of a bipolar transistor, as described by the Ebbers-Moll transistor model, includes a reverse saturation current (Is) term that exhibits device-to-device variation. A single-current method can be used if accuracy is not critical (4°C–8°C).

To cancel out the Is term, we use a two-current method. In the actual model, the required parameter is the current density of the base emitter junction, but this is simplified by making the geometry of the two diodes identical, and by scaling the current through the diodes. This circuit allows a single differential measurement that helps cancel noise appearing on the diode, improving the circuit's noise performance.

Because remote diode sensors have only one available diode, two differential measurements are taken at consecutive time intervals, which are then subtracted out to give a signal level of about 240 µV/°C. The time difference in the measurements does not provide the same noise immunity as that obtained using a single differential measurement but it is still acceptable. Performance can vary widely in designs that are integrated into high-density, high-power ICs; careful examination of manufacturers’ specifications is recommended.

PCB layout considerations: Degradation of analogue signal integrity on a PCB comes from EMI, thermocouple effects, trace resistance, and PCB leakage current. Digital signal integrity is mainly affected by trace length and impedance at the frequency of operation.

Series resistance should be minimized as far as possible, because the higher the trace impedance, the greater the likelihood that noise coupling will become an issue. To further mitigate series resistance, RDTS devices have internal compensation circuitry. A digital register that allows programming of an offset for the temperature reading reported by the device is fairly common and can be used to compensate for series resistance. The series resistance has a linear function for a specific sensor because the input stages of most RDTS devices can handle the common-mode offset caused by several ohms of series resistance.

Some RDTS devices implement series resistance cancellation but this method introduces more noise in the overall temperature reading. Devices without series resistance cancellation take the difference between two diode voltage readings at different current levels. Cancelling out series resistance is commonly achieved by introducing another current level and another diode voltage measurement. However, the voltage measurements do not happen simultaneously, making noise cancellation more difficult.

The first defence against noise issues is the circuitry within the RDTS itself. As shown in Figure 5, the analogue front end, ADC architecture, and additional digital filtering on the die all play a part in ensuring a stable, noise-free temperature reading. Most sensors include an analogue filter at the pins of the RDTS. Some implement a ΣΔ (sigma-delta) ADC, which includes a digital filter for first-stage averaging that is absent in successive approximation (SAR) ADCs. The final stage of defence is a digital filter included in most RDTS devices and commonly called a digital smoothing filter. Because there are product differences among manufacturers, device datasheets should be examined carefully.

Fig.5: RDTS functional block diagram - Image: ©Premier Farnell Ltd

Good layout is always important, especially with signal levels down to the 240 µV/°C level. Even with analogue sensors that have 10 mV/°C sensitivity, the signal level is still small and care is still needed. In digital environments, where noise levels can be many hundreds of millivolts, it's important to keep the analogue traces separated from the digital circuitry and digital traces: watch out for inductive coupling between traces on the PCB. Avoid routing a digital trace in parallel with the analogue trace. Should the digital trace need to cross the analogue trace, ensure that the two traces are perpendicular. Protect the analogue traces from noise coupling by using proper power supply bypass capacitors and following the manufacturer's suggestions. Without proper bypassing, improperly compensated bond wire inductance can induce noise in digital sensors.

A poorly chosen bypass capacitor can result in the PCB leaking current to the diode traces while improper cleaning procedures can also cause errors in the temperature readings of remote diode sensors. 20 nA of leakage can cause more than 0.2°C of error.

EMI is too broad a topic to be covered here but there are many good sources of information available. Thermocouple effects are negligible if the layout is limited to a few copper/solder joints and the signal level is in the sub-microvolts.

Sensor physical placement is critical to ensure that the temperature being measured is the one intended. The curve in Figure 6 shows the performance of the 2N3904/MMBT3904 transistor mounted in various ways to measure air temperature. The board-mounted through hole 2N3904 (T1) does not actually measure the air temperature even though the package was mounted off the board, as far away as the leads would allow, because the leads have a very good thermal conductive path to the sensor. This is good if you want to measure the board temperature but bad if you're trying to measure the ambient air temperature. Better alternatives are shown with the transistors marked T2 and T3. T2 is placed on a PCB off the main board. T3 is placed off the main PCB at the end of a twisted-pair shielded cable. T4 measures the local temperature as sensed by a National Semiconductor LM95214 quad input RDTS. The LM95214 can sense the temperature of four remote diodes as well as its own junction temperature (T4).

If we compare the performance of T1 through T4 we get the curve shown in Figure 6. A simple power resistor in a stagnant air environment provided heat on the back side of the board. As the resistor heats up so does the temperature of the board-mounted 2N3904 (T1) and LM95214 (T4). A thermocouple was used as a reference measurement of the air temperature. The shielded twisted-pair cable can be extended for many feet, but if this is the case, limit the capacitance to the RDTS manufacturer's recommendations and choose the gauge of the wire to minimize series resistance.

Fig.6: Temperature sensor placement - Image: ©Premier Farnell Ltd

It’s possible to compensate for most error sources, but not for all of them. The best results come from specifying a sensor with built-in noise immunity and following proper layout techniques. Make sure to mount the sensor properly so the target temperature zone or device is sensed properly, and be aware of the sensor's surroundings.

Getting started

An introduction to temperature sensors can be found on the Farnell website . Farnell also offers a number of evaluation kits and modules, as exemplified below:

Texas Instruments TMP112EVM Evaluation Board

The TMP112 is a digital output temperature sensor capable of reading temperatures to 12 bits of resolution. The TMP112 uses a two-wire, I2C™ and SMBus™ interface that allows up to four devices on one bus. The TMP112 is ideal for extended temperature measurement, and is also specified to operate between –40°C and 125°C. The TMP112EVM is a platform for evaluating the performance of the TMP112 under various signal, reference, and supply conditions.

Fig.7: TMP112EVM Evaluation board

Maxim MAX31730 Evaluation Kit

The MAX31730 evaluation kit (EV kit) provides the hardware and software graphical user interface (GUI) necessary to evaluate the MAX31730 3-channel remote temperature sensor in a μMAXM or TDFN package. The USB-powered EV kit includes a MAX31730 installed, as well as three external diode-connected transistors and a USB-to-SMBus/I2C interface.

Conclusion

Temperature sensing is a wide-ranging topic, with diverse sensor types, each with their own theoretical and practical considerations for choice and application. In this article we have endeavoured to make readers aware of these considerations and inform their project planning.

References

http://research.cs.tamu.edu/prism/lectures/iss/iss_l2.pdf

https://www.acromag.com/sites/default/files/RTD_Temperature_Measurement_917A.pdf

https://www.msm.cam.ac.uk/utc/thermocouple/pages/ThermocouplesOperatingPrinciples.html

NIST Standard Reference Database 60, Version 2.0

https://www.designworldonline.com/designing-with-thermistors

http://ww1.microchip.com/downloads/en/DeviceDoc/21895a.pdf

https://www.peaksensors.co.uk/thermocouple-design-guide

https://www.designworldonline.com/designing-with-thermistors

https://www.sensorsmag.com/embedded/temperature-sensor-tips-and-tricks

https://uk.farnell.com/sensor-temperature-sensor-technology?ICID=I-CT-TP-BROWSE-8

A guide to temperature sensor design. Date published: 15th April 2018 by Farnell